Press Brake Tonnage Calculator

Calculate the required tonnage for your press brake operation based on material type, thickness, bend length, and die opening. Get detailed bending force calculations.

Material Properties

Tooling Specifications

Bend Specifications

Additional Factors

Tonnage Results

Your press brake tonnage calculation will appear here

Calculation Breakdown

Detailed calculation breakdown will appear here after calculation

Press Brake Tonnage Fundamentals

Material Thickness

The thickness of your material is the most significant factor in determining required tonnage. Thicker materials require exponentially more force to bend.

Die Opening

Wider die openings require less tonnage but produce larger bend radii. Narrow dies increase tonnage requirements but allow tighter bends.

Bend Length

Longer bends require more total tonnage. The calculation is linear – double the length requires double the tonnage.

Material Strength

Materials with higher tensile strength require more force to bend. Stainless steel needs about 1.5x the tonnage of mild steel for the same thickness.

Bend Angle

Shallower angles (less than 90°) require more tonnage than standard 90° bends. The force required increases as the angle decreases.

Safety Factors

Always include a safety factor (typically 20%) to account for material variations, tool wear, and other real-world conditions.

Press Brake Tonnage Calculator: The Ultimate Guide to Accurate Bending Force Calculation

In metal fabrication, calculating the correct press brake tonnage is crucial for achieving precise bends without damaging your material or machine. A press brake tonnage calculator of Calculator Pro Tool simplifies this process by helping you determine the exact force required for your bending operations.

In this comprehensive guide, we’ll cover:

✅ How a press brake tonnage calculator works

✅ Key factors affecting tonnage requirements

✅ Step-by-step calculation method

✅ Benefits of using an online calculator

✅ Tips for optimizing your bending process

What Is a Press Brake Tonnage Calculator?

A press brake tonnage calculator is a digital tool that estimates the required force (in tons) to bend a metal sheet based on:

- Material type (steel, aluminum, stainless steel, etc.)

- Material thickness (in inches or millimeters)

- Bend length (the length of the bend line)

- Die opening (V-die width)

- Bend angle (typically 90°, but adjustable)

Using this calculator ensures you select the right press brake capacity, preventing machine overload and material defects.

Why Is Calculating Tonnage Important?

Accurate tonnage calculation helps:

✔ Prevent machine damage – Avoid overloading your press brake

✔ Improve bend quality – Reduce cracking or deformation

✔ Optimize tooling selection – Choose the correct die and punch

✔ Increase efficiency – Minimize trial-and-error setups

Without proper tonnage calculation, you risk:

❌ Machine failure – Excessive force can damage the press brake

❌ Poor bend quality – Wrinkling, cracking, or springback

❌ Wasted material – Scrap due to incorrect bending

How to Calculate Press Brake Tonnage (Manual Formula)

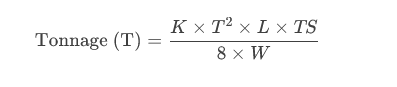

The standard formula for calculating press brake tonnage is:

Where:

- K = Factor (1.33 for air bending, 1.5 for bottoming, 2.0 for coining)

- T = Material thickness (inches)

- L = Bend length (inches)

- TS = Tensile strength (PSI)

- W = Die opening (inches)

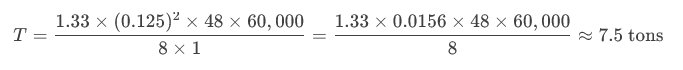

Example Calculation

Bending 0.125″ thick mild steel (60,000 PSI) with a 48″ bend length, 1″ die opening, and air bending (K=1.33):

For safety, add a 20% buffer, resulting in 9 tons required.

Key Factors Affecting Press Brake Tonnage

1. Material Type & Thickness

- Harder materials (stainless steel, high-carbon steel) require more tonnage than softer metals (aluminum, brass).

- Thicker materials exponentially increase tonnage needs (double thickness ≈ 4x force).

2. Bend Length

- Longer bends require more total force (linear relationship).

3. Die Opening (V-Die Width)

- Wider dies reduce tonnage but increase bend radius.

- Narrow dies require more force but allow tighter bends.

4. Bend Angle

- Acute angles (<90°) need more tonnage than 90° bends.

5. Bending Method

- Air bending (least force)

- Bottom bending (moderate force)

- Coining (highest force)

Benefits of Using an Online Press Brake Tonnage Calculator

Instead of manual calculations, an online press brake tonnage calculator offers:

🚀 Instant results – No complex math required

📱 Mobile-friendly – Use on any device

🔄 Adjustable parameters – Test different materials and thicknesses

📊 Visual breakdown – See how each factor affects tonnage

Tips for Optimizing Your Bending Process

- Use the Right Die – Match die width to material thickness (typically 6-12x thickness).

- Consider Air Bending – Requires less force than bottoming or coining.

- Check Material Grain Direction – Bend perpendicular to grain for better results.

- Apply Lubrication – Reduces friction and tonnage requirements.

- Regular Machine Maintenance – Ensure hydraulic systems are efficient.

Conclusion

A press brake tonnage calculator is an essential tool for metal fabricators, ensuring accurate force calculation for flawless bends. By understanding material properties, die selection, and bending methods, you can optimize your workflow and extend machine lifespan.