Accelerated Aging Calculator

Estimate equivalent aging time under accelerated conditions using the Arrhenius equation for product stability testing.

Test Parameters

Activation Energy

Aging Results

Your accelerated aging calculation results will appear here

Detailed Breakdown

Detailed breakdown will appear here after calculation

Regarding Accelerated Aging

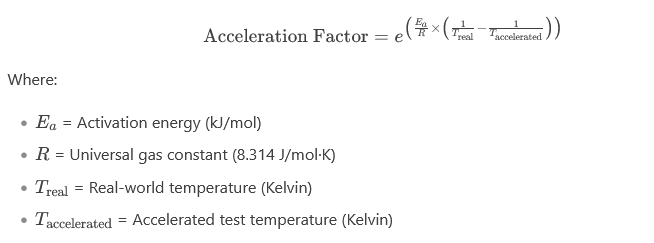

Arrhenius Equation

The Arrhenius equation describes the rate of reaction versus temperature relationship, so product shelf life can be estimated for different conditions.

Acceleration Factor

Increased temperatures drive chemical breakdown faster. Every 10°C rise generally doubles rates of reaction (Q10=2), although this depends on material.

Testing Standards

General standards consist of ISO 188, ASTM F1980, ICH Q1A, and others for accelerated aging methods of pharmaceutical stability testing.

Accelerated Aging Calculator: Calculate Product Shelf Life with Scientific Precision

In product quality and development, it is important to know how materials age with time. The Accelerated Aging Calculator is a useful tool derived from the Arrhenius equation to estimate real-world effects of aging within minutes, as opposed to years of natural aging. It is a scientific method that allows product manufacturers, researchers, and quality control engineers to forecast product stability and shelf life without having to wait for years of natural aging.

What is Accelerated Aging Testing?

Accelerated aging testing replicates long-term environmental effects in a short duration of time by exposing the products to elevated temperatures. Accelerated aging testing is widely practiced in:

- Medical devices (ISO 10993, ASTM F1980)

- Pharmaceuticals (ICH Q1A stability testing)

- Electronics (forecasting component longevity)

- Polymers and plastics (tests of durability)

How It Works: The Arrhenius Equation

It uses the Arrhenius equation:

How to Apply the Accelerated Aging Calculator

Step 1: Input Test Parameters

- Actual ambient temperature (°C): Normal storage conditions (e.g., ambient temperature 25°C).

- Accelerated temperature (°C): Higher test temperature (e.g., 60°C).

- Test duration (days): Period during which the product is subjected to the accelerated environment.

Step 2: Define Activation Energy

- Activation energy (kJ/mol): A material-dependent value (default = 80 kJ/mol).

- *Low (50 kJ/mol):* Less sensitive to temperature (e.g., some metals).

- *Medium (80 kJ/mol):* Characteristic of pharmaceuticals and polymers.

- *High (110 kJ/mol):* Temperature-sensitive materials.

Step 3: Optional Q10 Factor

- Q10 factor computes the rate of change of degradation per 10°C increase. If not known, the software computes it.

Step 4: Calculate & Interpret Results

The application provides:

✅ Acceleration measure (e.g., “12 times faster”)

✅ Same real-world aging duration (in years, months, or days)

✅ Thorough analysis of different temperature effects

Why Use This Calculator?

✔ Save Time & Costs – Predict years of aging in weeks.

✔ Improve Product Reliability – Identify weaknesses before going into the market.

✔ Compliance with Industry Standards – Comply with ISO, ASTM, and ICH standards.

✔ Optimize Storage Conditions – Determine safe temperature ranges.

Major Applications

1. Medical Device Sterility

- Estimate shelf life for sterile packaging (ASTM F1980).

- Ensure adherence to FDA/ISO standards.

2. Pharmaceutical Stability

- Predict drug degradation under different climates (ICH Q1A).

- Maximize storage and shelf life.

3. Material Science

- Test durability of polymer for auto/construction.

- Assess electronic component life.

Limitations & Considerations

⚠ Single-Step Reactions Only – Arrhenius model assumes uniform degradation. Complex multi-step reactions may need further testing.

⚠ Material-Specific Ea – Incorrect activation energy leads to incorrect predictions.

⚠ Non-Thermal Factors – Humidity, UV, and mechanical stress are not included.

Conclusion

The Accelerated Aging Calculator in the Calculator Pro Tool is an asset for companies that require precise shelf-life predictions and material stability assessments. With the Arrhenius equation, the tool enables manufacturers, researchers, and quality control specialists to age products in simulated years within weeks—saving time, expense, and product integrity.